Plug valves and ball valves are two of the most widely used quarter-turn valves in industrial and process applications. Both deliver quick shutoff and reliable isolation, yet they differ in design, sealing mechanism, and performance characteristics. Understanding these differences is essential when selecting the correct valve for a specific process condition, fluid type, or maintenance requirement. This article compares plug valves vs ball valves in terms of construction, operation, sealing performance, maintenance, and application suitability.

Overview of Quarter-Turn Valves

Quarter-turn valves derive their name from the fact that the internal closure element rotates just 90 degrees to move from fully open to fully closed. This simple operation enables quick actuation, compact design, and excellent compatibility with automation systems such as pneumatic or electric actuators.

Ball Valves

Ball valves use a spherical ball with a through-hole (bore) that aligns with the flow path when open and turns perpendicular to the line when closed. The ball sits snugly between two seats, which guarantees a tight seal and reliable shutoff. This design ensures low torque operation, minimal pressure drop, and smooth flow characteristics. Ball valves are available in a wide variety of configurations, including full-bore and reduced-bore designs, allowing engineers to balance flow capacity and pressure drop. Their simplicity and durability make them a top choice for general-purpose, clean media, and high-cycle automation applications.

Plug Valves

Plug valves, on the other hand, employ a cylindrical or tapered plug with a passageway drilled through its center. When the plug rotates 90 degrees, the passage either aligns with the flow path (open) or blocks it completely (closed). The plug can be sleeved or lubricated to provide a sealing surface, thus enabling rugged performance and superior resistance to clogging or fouling. Because the plug covers more surface area, plug valves can handle viscous, dirty, or particulate-laden fluids with less wear and better sealing reliability than some other valve types. Their robust design also offers excellent throttling capability and reduced risk of seat damage in challenging conditions.

Both valve types are valued for their fast actuation, compactness, and reliability. However, subtle differences in how they seal, operate, and handle certain media determine where each type excels.

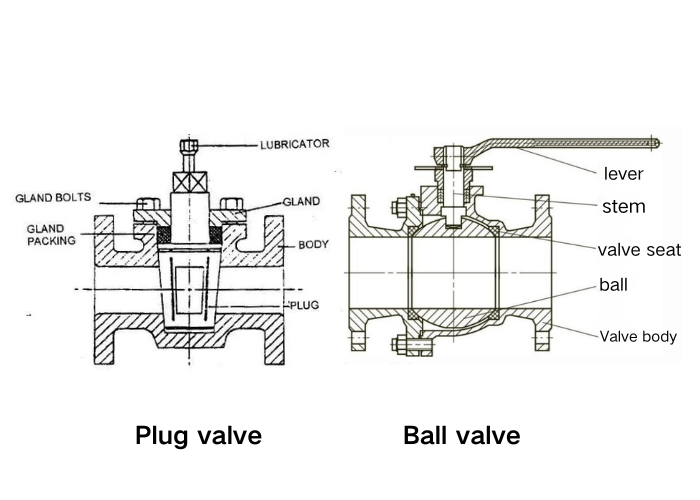

Construction and Design Differences of Plug Valves vs Ball Valves

Below is an overview of the internal structure and components of ball valves vs plug valves, detailing how their individual designs influence performance, sealing capability, and operational reliability.

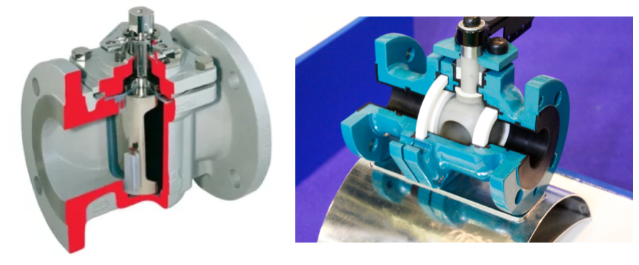

Ball Valve Construction

A ball valve consists of a spherical ball supported by seats that provide sealing against the flow. These seats are typically made of soft materials such as PTFE or RTFE for standard service, or metal for high-temperature or abrasive applications. Ball valves are available in two primary designs: floating ball and trunnion-mounted.

Floating ball valves rely on fluid pressure to push the ball against the downstream seat, achieving a tight shutoff. They are common in low to medium-pressure systems. Moreover, trunnion-mounted designs feature a fixed ball supported by bearings or trunnions at the top and bottom, reducing torque and making them suitable for high-pressure or large-diameter applications.

Ball valves typically come in one-piece, two-piece, or three-piece body constructions. Three-piece designs enable easier maintenance because the valve body can be serviced or cleaned in-line without disturbing the piping. Materials of construction include stainless steel, carbon steel, brass, and special alloys, depending on media compatibility and pressure requirements.

- Full-Bore vs. Reduced-Bore: Full-bore designs ensure minimal flow restriction, while reduced-bore valves offer compactness and cost efficiency.

- Seating Materials: PTFE offers chemical resistance and low friction, while metal seats are suitable for handling abrasive or high-temperature fluids.

- End Connections: Available in flanged, threaded, or welded ends, allowing versatility across industries.

Plug Valve Construction

Plug valves feature a cylindrical or tapered plug that rotates inside the valve body. The plug has a port that aligns with the pipeline when open and rotates perpendicular when closed. As a result, the sealing occurs between the plug surface and the body or a sleeve insert.

There are two main types of plug valves:

- Lubricated plug valves use a sealing grease or lubricant injected between the plug and the body to ensure a tight seal and reduce wear. These are often used in high-pressure or hydrocarbon services.

- Non-lubricated plug valves feature a PTFE or fluoropolymer sleeve, which provides a low-friction, corrosion-resistant interface. Thus, eliminates the need for frequent lubrication and maintenance.

Generally, plug valve bodies consist of materials such as ductile iron, carbon steel, stainless steel, or specialty alloys for chemical resistance. Furthermore, their robust design makes them ideal for severe process conditions where corrosion, abrasion, or solids are present.

- Sleeve-Lined Construction: Reduces friction, enhances corrosion resistance, and minimizes maintenance.

- Tapered Plug Design: Provides self-sealing action and improved wear compensation.

- Maintenance Simplicity: Allows easy disassembly and inline adjustment.

Key Differences

While the ball valve relies on seats to seal against a rotating sphere, the plug valve depends on close contact between the plug and its body or sleeve. This distinction impacts operating torque, wear characteristics, and maintenance requirements.

Operational Capabilities

One of the most noticeable distinctions between plug and ball valves lies in their operational performance under various process conditions. Torque, flow dynamics, and automation compatibility all play a key role in determining which valve best suits a given application.

Torque Requirements

Plug valves typically demand higher operating torque due to the extensive contact area between the plug and valve body. This high frictional resistance, while increasing actuation effort, also enhances sealing integrity in abrasive, viscous, or polymerizing fluids. In manual systems, this often necessitates gear- or lever-assisted operation, whereas automated setups utilize high-torque pneumatic or hydraulic actuators. Ball valves, with their low-friction seats and floating or trunnion-supported ball designs, operate smoothly with minimal torque, making them better suited for high-cycle or automated service.

- Plug Valves: High torque; beneficial for abrasive or slurry media; suited for rugged, intermittent operation.

- Ball Valves: Low torque; ideal for frequent actuation and precise automation.

Flow Characteristics

Ball valves provide a true full-bore flow path, minimizing pressure drop and allowing unrestricted fluid passage. This makes them optimal for gas pipelines, clean liquid transfer, and utility systems where energy efficiency and low turbulence are priorities. In contrast, plug valves, especially tapered plug designs, offer better throttling control and can manage flow modulation in systems that handle viscous, fouling, or multiphase fluids. Their streamlined internal geometry reduces areas where solids might accumulate, maintaining predictable flow even under challenging media conditions.

- Ball Valves: Full-bore flow; minimal ΔP; superior for clean gases and liquids.

- Plug Valves: Controlled throttling; reliable under slurry, viscous, or dirty conditions.

Automation Compatibility

Both valve types are readily adaptable to electric, pneumatic, or hydraulic actuators. Ball valves are favored in automated networks due to their low torque requirements, lightweight and compact design, and because they allow the use of smaller, faster, and more energy-efficient actuators. Plug valves, though fully automatable, often require more robust actuator systems to overcome seating friction, making them a better fit for slower, high-torque actuation where reliability and seal integrity take precedence over actuation speed.

- Ball Valves: Widely automated; compatible with compact actuators; ideal for remote or PLC-controlled systems.

- Plug Valves: Automation-ready; preferred in heavy-duty, slow-cycle applications demanding tight shutoff.

In essence, plug valves provide torque-driven durability and adaptability for challenging process media, while ball valves deliver precision, speed, and efficiency for clean, automated flow control.

Sealing Performance and Leakage Control of Plug Valves vs Ball Valves

Sealing performance is a critical factor in valve selection, particularly in processes where tight shutoff and emission control are required.

Ball Valves

Soft-seated ball valves utilize PTFE, RTFE, or other polymer-based materials, providing an exceptionally tight seal that often achieves bubble-tight shutoff under ANSI Class VI standards. These valves are ideal for clean gases and liquids where surface imperfections and particle interference are minimal. In engineering terms, their sealing reliability is a function of precise seat preload, surface finish, and pressure-assisted contact between the floating ball and the downstream seat.

For more demanding service conditions, such as abrasive fluids, elevated temperatures above 250°C, or high-pressure differentials, metal-seated ball valves offer enhanced durability. The metal-to-metal interface, often surface-hardened or coated with materials like tungsten carbide or chromium oxide, provides resistance against erosion and thermal expansion. These designs maintain sealing integrity even under pressure fluctuations and are less prone to soft seat deformation.

Key Technical Highlights for Ball Valves:

- Soft Seats: Offer low torque and superior sealing in clean service.

- Metal Seats: Provide long-term reliability in abrasive, high-pressure, or high-temperature conditions.

- Pressure Ratings: Available from ANSI Class 150 to 2500, depending on configuration.

- Emission Control: Designed to meet API 641 and ISO 15848 standards for low fugitive emissions.

Plug Valves

Plug valves employ either lubricated or sleeved sealing systems, each suited for specific engineering conditions.

- Lubricated Plug Valves rely on the injection of sealant between the plug and body, forming a thin film that prevents metal-to-metal contact and seals micro-paths to prevent leakage. This design is highly reliable in hydrocarbon or gas service, where temperature and pressure cycling can cause other valve types to leak. The grease also serves as a corrosion inhibitor, enhancing longevity in offshore and refinery environments.

- Sleeved (Non-Lubricated) Plug Valves use a PTFE, PFA, or fluoropolymer sleeve that envelops the plug, providing a low-friction, self-lubricating interface. This configuration eliminates the need for periodic lubrication while maintaining excellent sealing performance, even in chemical or slurry service. The self-cleaning action between the plug and sleeve prevents the buildup of solids and ensures stable torque characteristics. The sleeve material selection is based on chemical compatibility, pressure, and temperature, with options for anti-static or fire-safe designs.

Key Technical Highlights for Plug Valves:

- Sleeve-Lined Construction: Reduces friction, prevents galling, and resists chemical attack.

- Lubricated Design: Allows re-lubrication for seal restoration and corrosion protection.

- Operational Range: Suitable for pressures up to ANSI Class 600 and temperatures up to 250°C (depending on material selection).

- Fugitive Emission Control: Engineered to meet stringent EPA and ISO emission standards.

When To Choose

- Ball Valves: Select for applications requiring precise shutoff, low operating torque, and minimal pressure drop in clean service. Ideal for compressed gases, process water, and high-cycle automation.

- Plug Valves: Choose for viscous, corrosive, or slurry media where solids or chemical aggression could compromise ball valve seats. Perfect for chemical processing, pulp and paper, and polymer transfer systems.

Maintenance and Serviceability of Plug Valves vs Ball Valves

Maintenance considerations often determine the total lifecycle cost of a valve.

Ball Valves

These valves are relatively low-maintenance. In most designs, soft seats and seals can be replaced without needing to remove the valve from the line. However, exposure to particulates or abrasive fluids can accelerate seat wear. Three-piece body ball valves enable quick disassembly and in-line servicing, making them a practical choice for process plants with routine maintenance schedules.

Plug Valves

Plug valves are built for durability and ease of maintenance. Many designs allow inline servicing and seal adjustments without removing the valve from the piping. Lubricated plug valves, however, require periodic injection of sealing grease to maintain performance. Non-lubricated sleeve-lined plug valves significantly reduce maintenance needs, offering long-term reliability without frequent intervention.

Maintenance Insight

Plug valves excel in demanding services where frequent cleaning or adjustment is necessary, while ball valves thrive in clean, automated, or general-purpose installations. Technically, plug valves are better suited for handling viscous, slurry, or polymerizing fluids because their simple internal design allows for easy cleaning and in-line maintenance. Their self-wiping action helps prevent buildup, while lubricated versions can restore sealing performance through the injection of grease, ensuring reliability under harsh conditions.

Ball valves, by contrast, provide low-torque operation and excellent shutoff performance in clean service environments such as compressed air, gas, and water systems. Their smooth bore minimizes pressure loss, and trunnion-mounted options maintain consistent torque under high pressure. Maintenance is typically limited to periodic seat or stem packing inspection, making them ideal for automated systems where reliability and low upkeep are priorities.

Application Suitability

| Application | Preferred Valve Type | Reason |

| Chemical and corrosive fluids | Plug Valve | Resistant to corrosion and buildup; sleeve-lined for low emissions |

| Gas and hydrocarbon service | Ball Valve | Tight shutoff and low leakage; ideal for pipeline isolation |

| Slurry or viscous media | Plug Valve | Self-cleaning action and erosion resistance |

| Clean water and air service | Ball Valve | Compact, low torque, and cost-effective |

| High-temperature or abrasive service | Metal-Seated Ball Valve | Superior wear resistance and durability |

| Frequent throttling | Plug Valve | Better control characteristics and modulation capability |

Advantages and Limitations

Understanding the performance trade-offs between plug and ball valves helps engineers optimize system design, maintenance, and lifecycle efficiency.

Advantages and Limitations of Plug Valves

Advantages

- Rugged Construction: Compact, simple, and heavy-duty body suitable for high-pressure and high-temperature service.

- Excellent for Harsh Fluids: Handles corrosive, viscous, and particulate-laden media without clogging or seat erosion.

- In-Line Maintenance: Can be disassembled and serviced without removing from the pipeline; ideal for process-critical systems.

- Adjustable Sealing: Plug position can be fine-tuned to restore tight shutoff and compensate for wear.

- Throttling Capability: Provides moderate flow control and precise modulation in viscous or multiphase fluids.

Limitations

- Higher Torque: Requires greater actuation torque, often demanding gear or hydraulic assistance.

- Heavier Body: A larger mass compared to equivalent ball valves increases space and support requirements.

- Lubrication Needs: Lubricated designs require periodic maintenance to prevent seizure or leakage.

- Energy Cost: Slightly higher pressure drop due to plug geometry, particularly in partially open positions.

Advantages and Disadvantages of Ball Valves

Advantages

- Bubble-Tight Shutoff: Achieves ANSI Class VI sealing for zero-leak performance in clean media.

- Low Pressure Drop: Full-bore design minimizes flow resistance and energy losses.

- Compact and Lightweight: Easier to install, automate, and support compared to plug valves.

- Wide Application Range: Handles broad temperature (-50°C to 500°C) and pressure (up to Class 2500) conditions.

- Quick Operation: 90° actuation allows rapid shutoff and precise control in automated systems.

Limitations

- Poor Slurry Handling: Not recommended for abrasive, solid-laden, or polymerizing fluids, which can damage seats.

- Seat Degradation: Soft-seated types may deteriorate under high temperature, chemical exposure, or pressure cycling.

- Limited Throttling: Designed primarily for on/off control; throttling may cause cavitation or uneven wear.

QRC Valves Offerings and Expertise

QRC Valves supplies a wide range of quarter-turn valves designed for performance and durability across industrial sectors.

- Plug Valves: QRC offers non-lubricated plug valves, renowned for their drop-tight shutoff, corrosion resistance, and low fugitive emissions performance.

- Ball Valves: QRC’s ball valve inventory includes floating and trunnion-mounted designs from top manufacturers, engineered for API and ASME compliance in oil, gas, and process applications.

Whether you’re managing corrosive fluids, high-pressure hydrocarbons, or utility water, QRC Valves provides expert guidance to match your valve to your operating conditions. Get in touch today for expert advice.

Recent Comments