RESOURCES

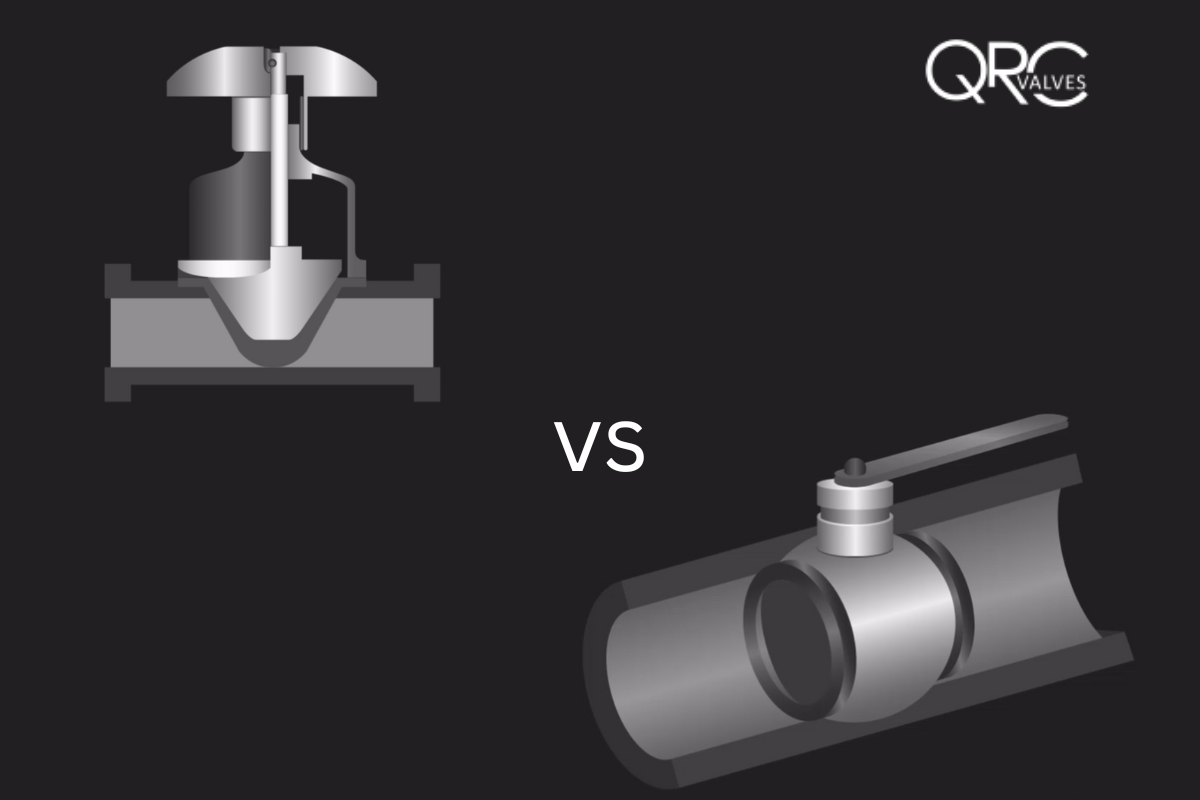

Gate Valves vs Ball Valves

Gate valves and ball valves are two common types of valves used in various industrial applications. Each offers unique benefits and limitations. In this article,

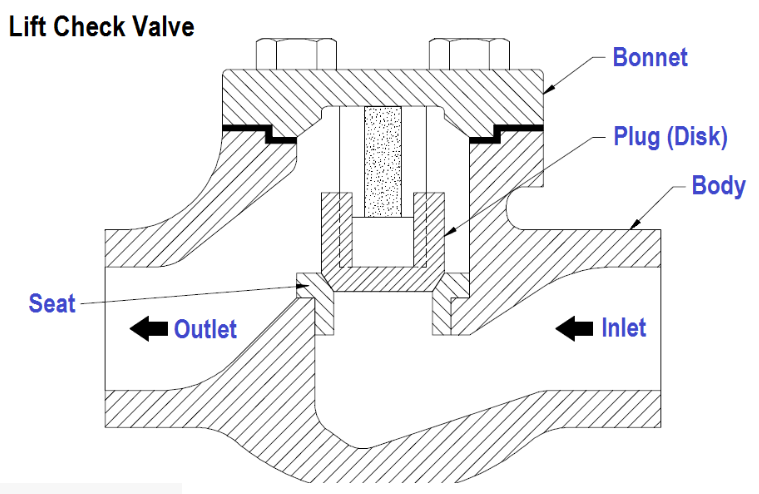

Piston Check Valve

Piston check valves are essential for controlling fluid flow in various industrial applications. They belong to the check valve family, which permits only unidirectional flow

Valve Seat Selection Guide

Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. This article reviews valve seat types, key considerations

API 594 – Key Elements

API 594 is an industry-standard for check valves with widespread application, especially in the petrochemical and oil & gas industries. The standard ensures that the

Intro to Gate Valves

Gate valves serve in isolation applications where they can either completely shut off or allow full flow in a pipeline. Their compatibility with a variety

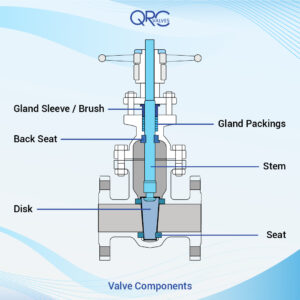

Valve Backseat

A valve backseat is a common design feature in gate valves, as well as globe valves, serving in isolation applications. This article reviews how a valve backseat works, its testing procedure, and when to deploy it to maintain system reliability.

NACE Compliant Valve

Reviews the requirements for an NACE compliant valve, then summarizes some key elements of the NACE MR0175 and NACE MR0103.

OS & Y Valve

The OS & Y valve, known as ‘outside stem and yoke’ is a configuration common in several industrial applications.

High Pressure Valves

High-pressure valves are important in controlling the flow, direction, and pressure of process and piping systems.

High Temperature Valves

High temperature valves refer to industrial valves that have the capacity to perform at significantly high temperatures. They can do this because manufacturers design them using durable and versatile metallic materials, which have extremely high melting points.

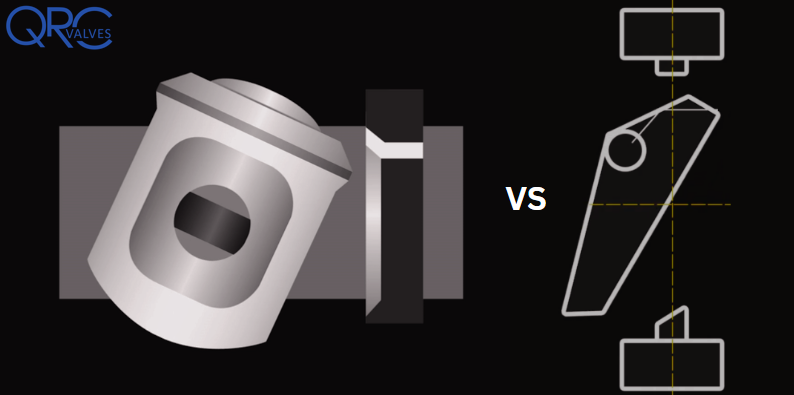

Butterfly Valve vs Ball Valve

When it comes to flow regulation in industrial applications, it is common to have to choose between a butterfly valve or a ball valve. Both are quarter-turn rotary valves that serve similar purposes, but distinct features make them suitable for different situations.

Severe Service Valves

In the realm of valves, the term ‘severe service’ signifies operating conditions that pose challenges beyond the ordinary. A severe service valve must withstand extreme conditions such as high pressures, corrosive environments, or fluctuating temperatures.

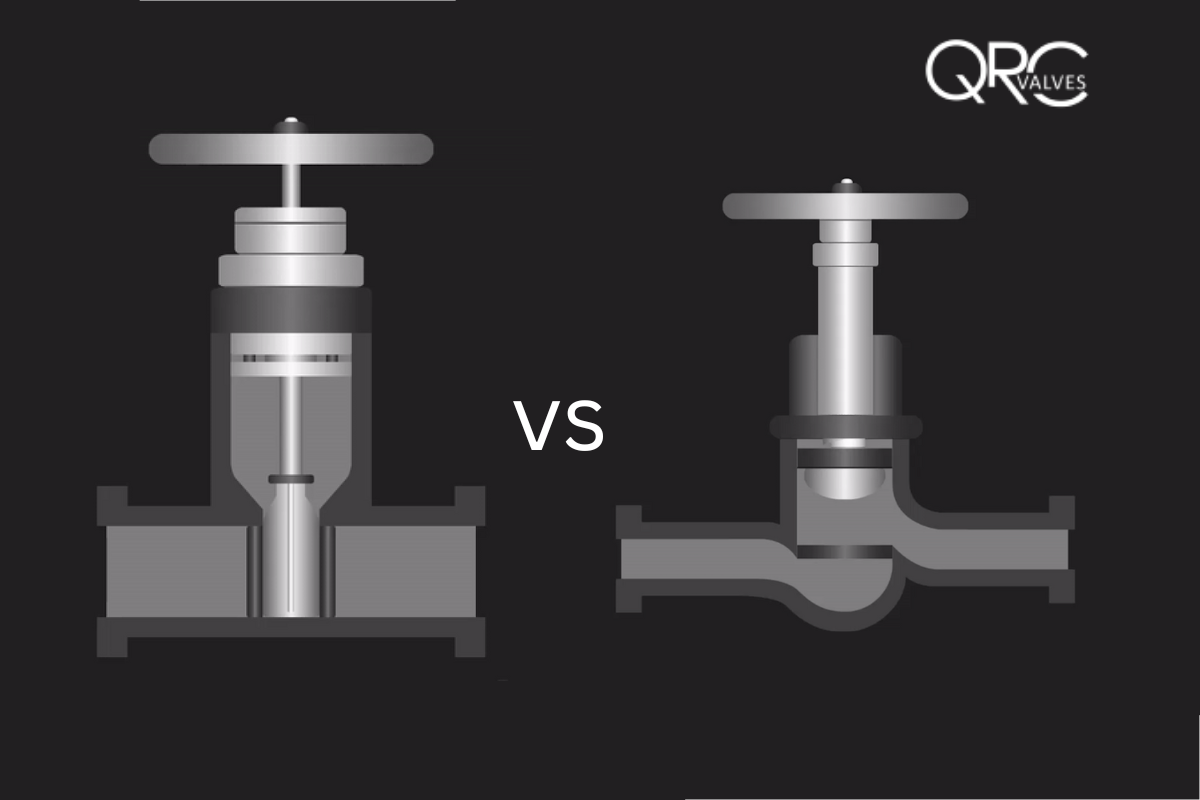

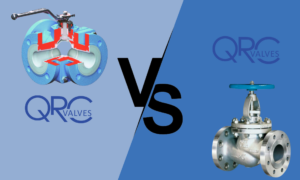

Gate vs Globe Valves

Gate vs. Globe Valves In fluid control systems, selecting the appropriate valve is crucial for ensuring efficient operation and longevity of the system. Among the

Valve Maintenance

Valves might experience wear, tear, corrosion, leading to leaks, blockages, or failure. Therefore, valve maintenance becomes essential for any facility operation.

Types of Butterfly Valves

The types of butterfly valves vary according to material attributes and product configuration. However, all types see frequent use in…

Lined Valves

Lined Valves Lined valves play a crucial role in industrial setups where reliability and precision are paramount. The design of these specialized valves enables them

Cast vs Forged Valves

Cast Versus Forged Valves Valves are indispensable parts of any industrial system, but they are not all made the same way. Of all the methods,

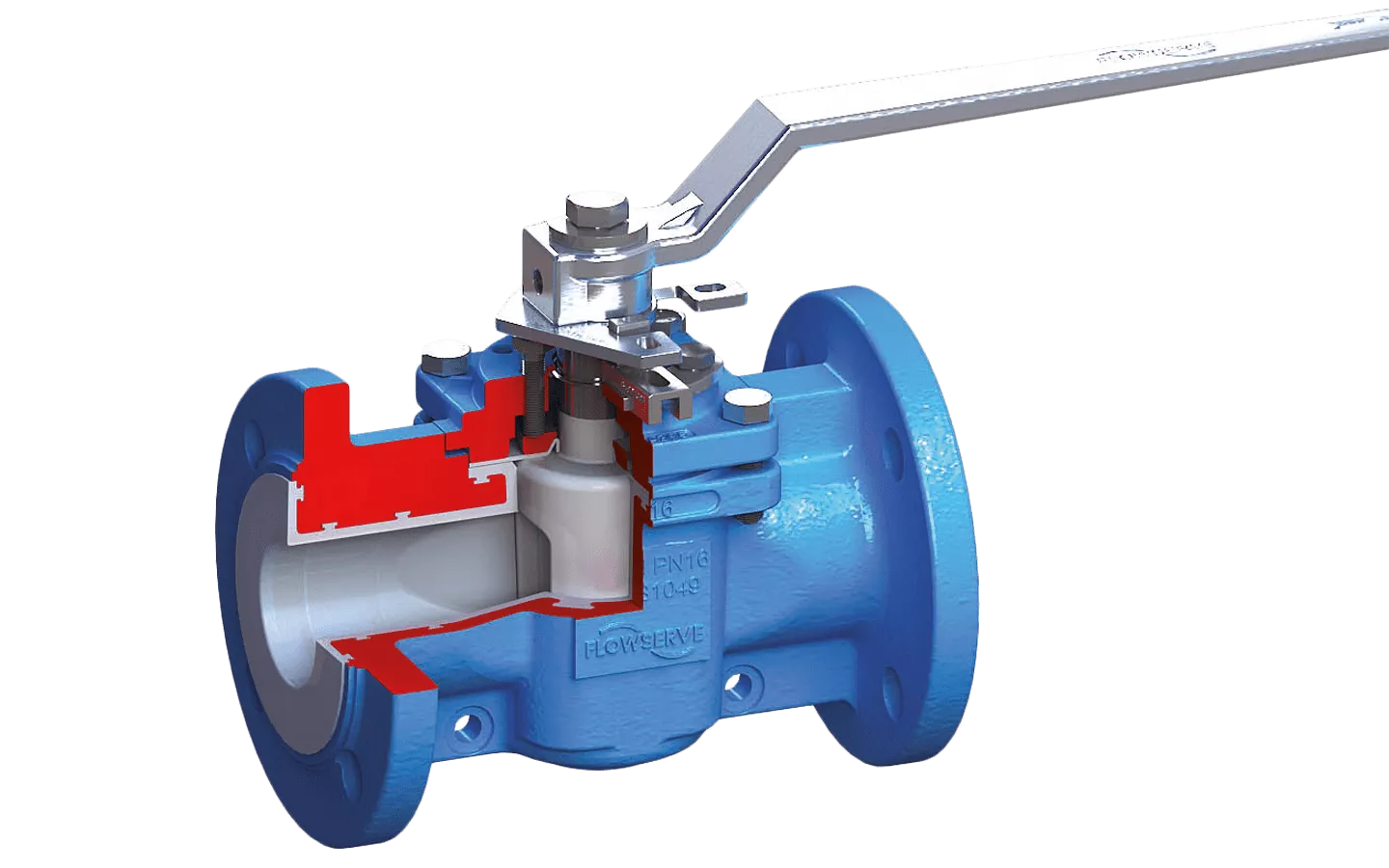

Diaphragm Valve vs. Ball Valve

Ball Valve vs. Diaphragm Valve In some industrial applications, diaphragm valves compete with ball valves. Each present a distinct set of advantages and disadvantages. In

Industrial Globe Valves

Industrial Globe Valves Globe valves remain a popular option for industrial applications as their design allows them to excel in both throttling and shut-off purposes.

Valves Used in the Chemical Industry

Valves are critical components in the chemical industry as they perform several functions. Not only do they deliver precise control and dosing, they also monitor pressure, protect other equipment, and must be compatible with the flow media.

Emergency Shutdown Valve

Emergency Shutdown Valve An emergency shutdown valve, frequently referred to as a safety shutdown valve, quickly halts fluid flow in an emergency or potentially hazardous

Direct Acting vs Reverse Acting Actuator

Direct Acting vs Reverse Acting Actuator Actuators perform important functions in valves, especially control valves. Common operations performed include fully opening, fully closing, and providing

Globe Valve Flow Direction

Globe valves are the one most common in the industry. Learn their characteristics, and what dictates globe valve flow direction.

Automated Valves

Automated valves do not require manual efforts for their operation. Rather, they possess an actuator and control system that automatically performs the opening, closing, and regulation of the valve. Benefits of this system include increase in efficiency and operator safety. In this article, we review how automated valves work, as well as the functioning of automated gate, globe, and butterfly valves.

Stainless Steel Valves

Stainless steel valves are one of the most common types because they offer great durability at a relatively low cost. Learn more about stainless steel valves and compare them vs other valve materials.

Functions of a Check Valve

A check valve is common in control applications to ensure that the flow of liquid or gas is in only one direction. Learn the functions of a check valve in industry, its application in various types of systems, and functionality vs a non-return valve.

WCB Valve – Meaning, vs. WCC

WCB Valve – Meaning, vs. WCC WCB in valve means Weldable Cast Steel with a B grading. In this article, we discuss the meaning of

RPTFE Seat – Applications in Industry, vs. PTFE

RPTFE Seat – Applications in Industry, vs. PTFE RPTFE stands for Reinforced Polytetrafluoroethylene and provides a common valve seat coating material. This is largely because

CV of Valves

CV of Valves The CV of valves refers to their flow coefficient and provides one of the important parameters when selecting a valve for an

Ball Valves vs. Globe Valves

Ball Valves vs. Globe Valves Valves are mechanical or electro-mechanical devices commonly found in a myriad of industrial processes, manufacturing, and maintenance operations. These devices

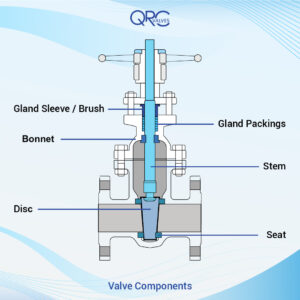

Gate Valve Components

Gate Valve Components A gate valve is typically used in industrial settings to completely restrict flow, or to fully allow flow when it is in

Leaking Gate Valve – Causes, Types, and Fixes

Leaking Gate Valve – Causes, Types, and Fixes A leaking gate valve may disrupt the efficiency, performance, and environmental compliance of any system. In this

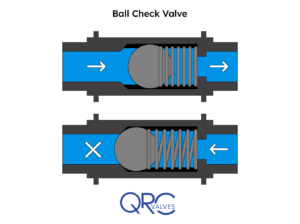

Ball Check Valves – Operation, Diagram vs. Swing Valves

The purpose of using a ball check valve is to prevent reverse flow in a pipe. Ball check valves achieve this by using a spherical ball inside the flow path that permits flow in only one direction.

Actuated Valve – Working Principle and Types

Actuated Valve – Working Principle and Types Actuated valves provide the foundation of flow control for any modern process system. An actuated valve operates externally

API 6D Valves – Types, vs. API 598

API 6D Valves – Types, vs. API 598 API 6D is the American Petroleum Institute’s specification for pipeline and pipeline valves in the petroleum and

Plug Valves – Types, Construction, and Applications

Plug Valves – Types, Construction, and Applications Plug valves utilize conical and cylindrical plugs to stop or throttle flow in a system. The plug has

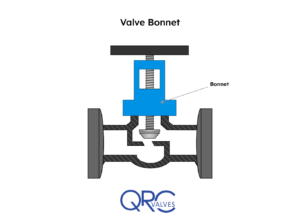

Valve Bonnet – Types, Leakages, and Repair

Valve Bonnet – Types, Leakages, and Repair Generally, the classification of valve bonnets corresponds to how it fastens to the valve body. In this article,

Fugitive Emission Valves

Fugitive Emission Valves Fugitive emission valves have been qualified according to industry standards against the leakage or unintentional release of vapor or gasses. The use

Rising Stem Valves – Ball, Gate, vs. Non-Rising

Rising Stem Valves – Ball, Gate, vs. Non-Rising Rising stem valves provide a stem that rises or falls as the valve opens or closes. This

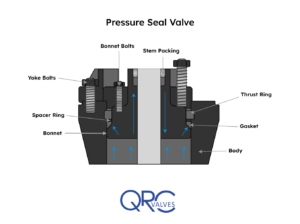

Pressure Seal Valves – Working Principle, vs. Bolted, Gaskets

Pressure Seal Valves – Working Principle, vs. Bolted, Gaskets The design of pressure seal valves is specifically for high-pressure applications typically in excess of

Cryogenic Valves – Uses, Types, Standards, and Testing

Cryogenic Valves – Uses, Types, Standards, and Testing Cryogenic valves can withstand and operate effectively at extremely cold temperatures. They serve in a variety of

Triple Offset Butterfly Valve – Benefits, Drawing, vs Other Offsets

Triple Offset Butterfly Valve – Benefits, Drawing, vs Other Offsets Choosing the right type of butterfly valve is key to every application. The available range

Valve Corrosion – Causes, Allowance, & Prevention

Valve Corrosion – Causes, Allowance, & Prevention Valves, typically composed of metal, serve as a conduit to a variety of fluids. As such, a valve

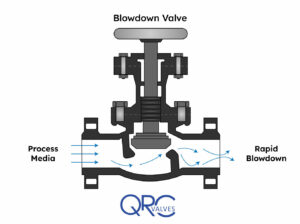

Blowdown Valve – Working Principle, Types, Diagram, Applications

Blowdown Valve – Working Principle, Types, Diagram, Applications Working Principle of Blowdown Valves In industry, blowdown valves often attach to equipment where water is the

Valve Testing – Hydrostatic, Pneumatic, Shell, Seat, Fire…

Valve Testing – Hydrostatic, Pneumatic, Shell, Seat, Fire… The realization of safe and smooth operations of industrial processes is heavily reliant on valves performing their

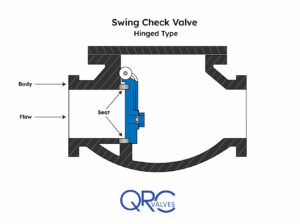

Swing Check Valve – Diagram, Types, and Applications

Swing Check Valve – Diagram, Types, and Applications A swing check valve allows forward flow and blocks the reverse flow. It provides a strong option

Valve Trim – What It Is, Plug Profiles, Parts, Chart, and Selection Process

Valve Trim – What It Is, Plug Profiles, Parts, Chart, and Selection Process Valve trim refers to the operating parts of a valve that are

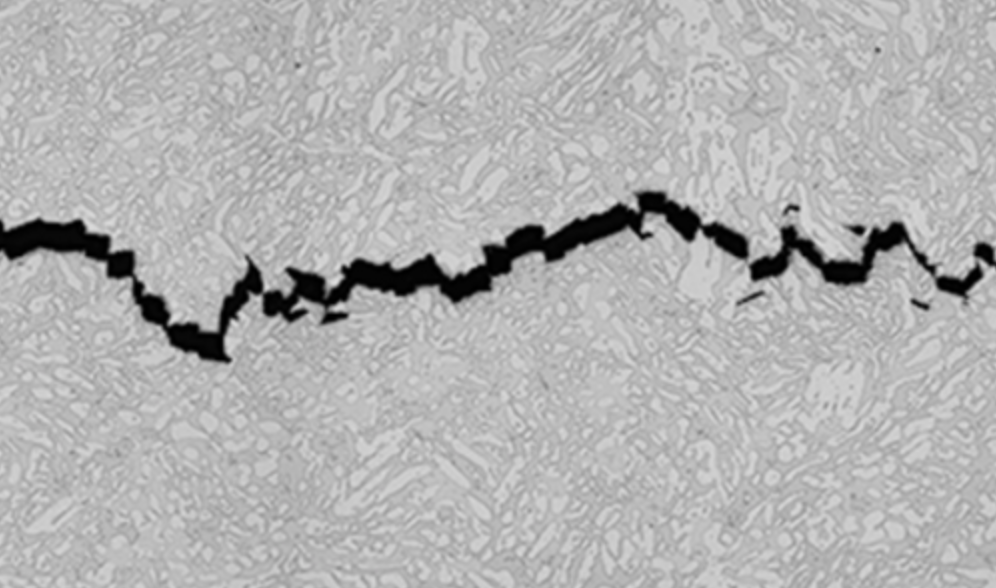

What is Hydrogen Induced Cracking (HIC)?

What is Hydrogen Induced Cracking (HIC)? Hydrogen-induced cracking (HIC), or hydrogen embrittlement, is a chemical phenomenon that causes metal alloys to fracture due to a

API Monograms

NEWS & RESOURCES SEPTEMBER 08, 2021 API Monograms API has a monogram program: API does monograms for API 600, API 602, and API 594.As of

Killed Steel

NEWS & RESOURCES AUGUST 17, 2021 Killed Steel Killed steel, sometimes called deoxidized steel, is steel that has been entirely deoxidized by adding an agent before

Material and Trim Temperature Limits

NEWS & RESOURCES JULY 01, 2021 Material and Trim Temperature Limits Blow Down service is the removal of hot water, usually from the bottom of a

Orbit Rising Stem Ball Valves Order

NEWS & RESOURCES MAY 25, 2021 Orbit Rising Stem Ball Valves Order Our Stafford sales and warehouse teams worked tirelessly on a $550k Orbit valve order

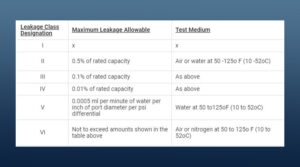

Class Seat Leakage

Class Seat Leakage HYDRO TESTING – CLASS I to IVCLASS SEAT LEAKAGE The term “Class” seat leakage comes from ANSI / FCI 70-2. This is

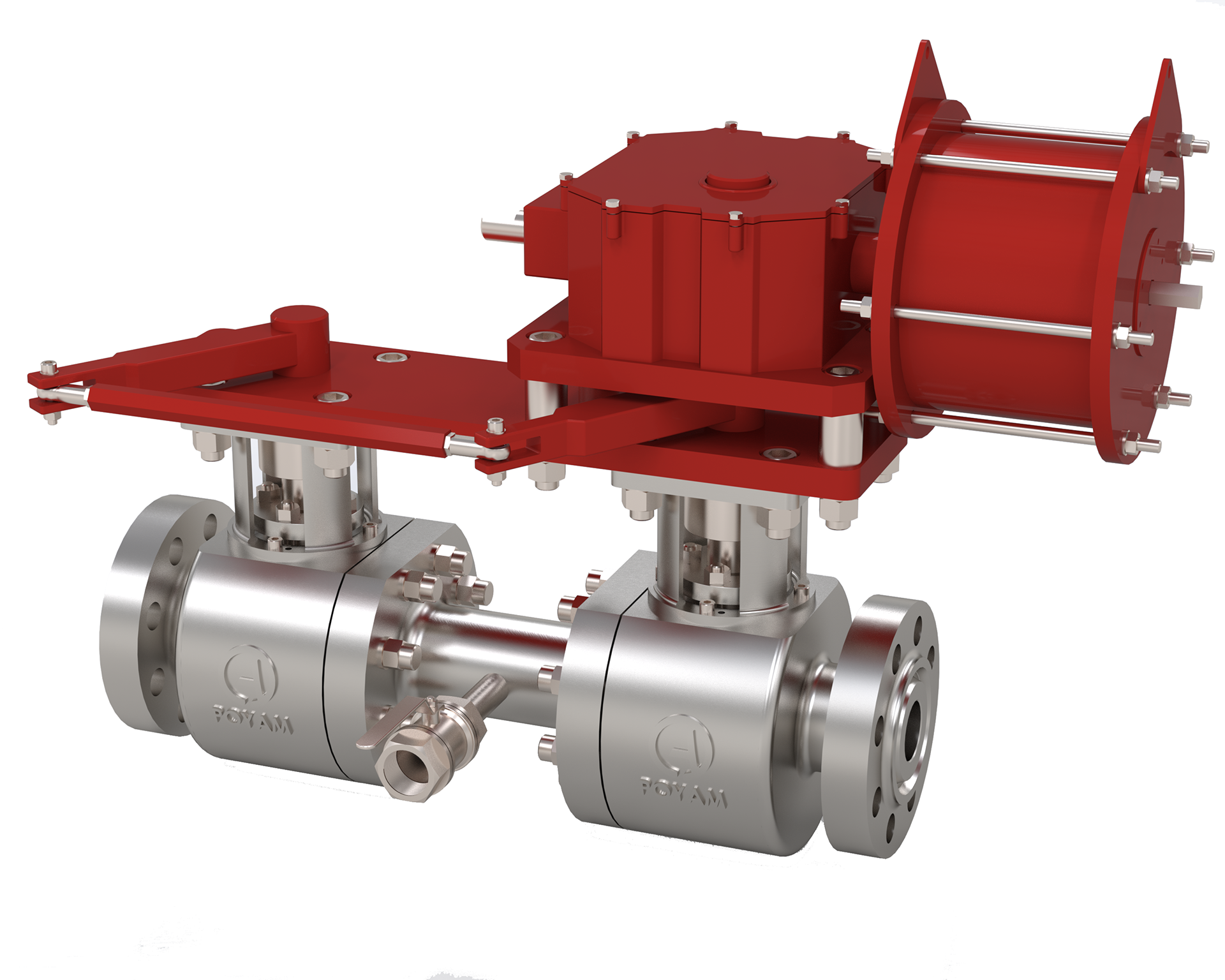

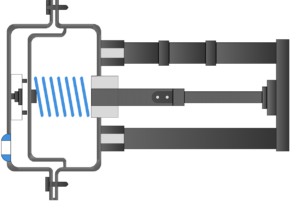

Bypass and Equalizer Combination

NEWS & RESOURCES FEBRUARY 10, 2021 Bypass and Equalizer Combination The 3-line bypass and equalizer combination pictured above allows the end user to achieve a variety

Cameron’s ORBIT Rising Stem Ball Valve

NEWS & RESOURCES OCTOBER 27, 2020 Cameron’s ORBIT Rising Stem Ball Valve We had an exciting opportunity to write about Cameron’s ORBIT rising stem ball valve. The