Automated valves do not require manual efforts for their operation. Rather, they possess an actuator and control system that automatically performs the opening, closing, and regulation of the valve. Benefits of this system include increase in efficiency and operator safety. In this article, we review how automated valves work, as well as the functioning of automated gate, globe, and butterfly valves.

How Automated Valves Work

The essence of automating valves is for them to be self-acting and respond promptly to process variables or certain working conditions. To achieve this, sensors detect changes to quantities such as pressure and temperature, then the control system transmits a signal to the actuator to take the appropriate action. Although the general principle of automated valves are the same, the working principle varies according to the type of actuator in use. Common types include pneumatic, hydraulic, and electric actuators.

Pneumatic Actuators

These actuators operate by air pressure, usually between 3 to 8 bar, depending on the size and speed of the valve. In an automated valve, the control unit sends air to the diaphragm or piston connected to the stem to operate the valve. The air signal coming into the valve depends on a measured variable such as the process temperature or pressure, so does not require human intervention.

When air pressure closes the valve and spring action opens it, the actuator is termed direct acting, and the valve is normally closed. However, if air pressure opens the valve and spring action closes it, the actuator is reverse acting and the valve is normally opened. In addition, there are double acting actuators where air comes in from both sides of the diaphragm. So, the position of the valve is a function of the differential pressure across the diaphragm.

Hydraulic Actuators

Hydraulic actuators utilize fluid pressure from oil or water to control valves in a manner similar to pneumatic actuators. Also, a piston converts signal pressure into valve stem motion with a spring force returning the valve to its normal position on loss of pressure. They are suitable for high-force applications, but do not operate valves as quickly as pneumatic actuators. Generally, the fluid supply line to the valve is one inch or less to ensure speed and high pressure for controls. A solenoid activates to allow fluid to enter and control the valve.

Electric Actuators

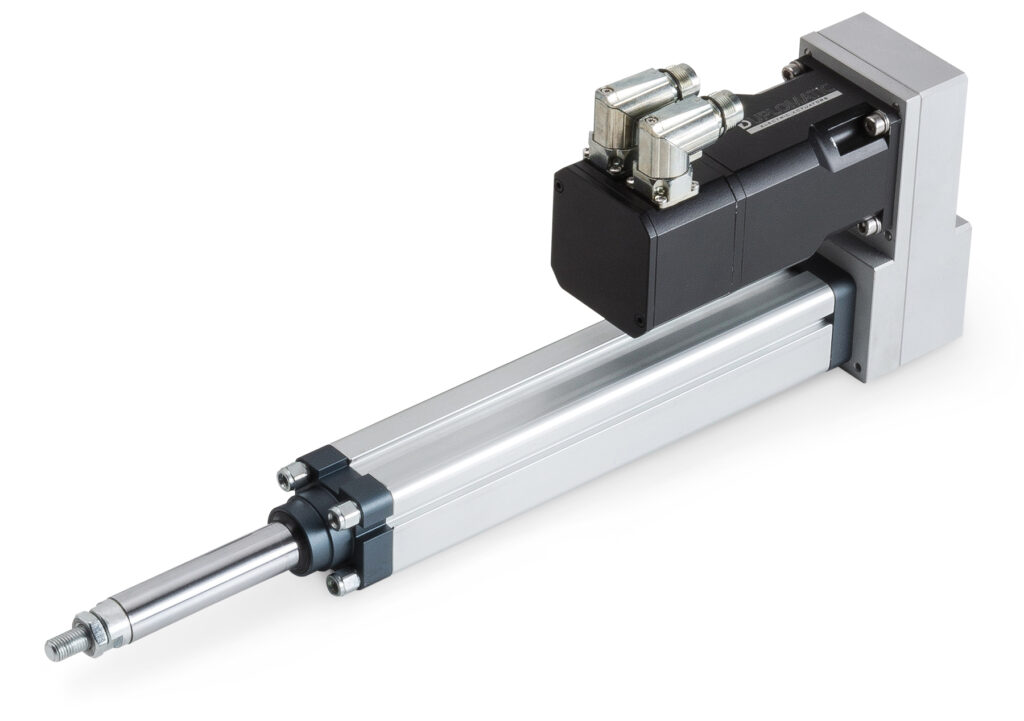

Electric actuators typically use a reversible, high-speed motor to open, close, and regulate valves. In comparison to pneumatic and hydraulic, they are more energy efficient, non-toxic, and quiet. Also, the connection from the motor to the valve is typically via a gear train that reduces the speed and increases the torque delivery to the stem. Using a reversible motor enables operation of the valve in both directions (open and close). Because electric actuators offer quick response and high torque, they are ideal for large and high pressure valves.

Considerations when Automating Valves

The selection of the type and size of the actuator for automated valves requires the consideration of several factors.

Torque Rating

This is a critical detail in the automation of valves, as the torque rating of a valve influences actuator requirements. Proper sizing of the actuator ensures that it can open or close the valve whenever it is called upon. The torque rating of valves varies according to the valve type and size, with quarter-turn valves requiring the least.

Another factor that affects torque rating is the flow media pressure. When determining a valve torque rating, breakaway torque provides a key parameter as it is the highest torque requirement in the operation of the valve. Breakaway torque is the rotational force required to open a valve from a fully closed position. It is higher than the running torque of the valve, and its value is typically quoted by valve manufacturers in terms of nominal pressure.

Safety Factor

After determining the torque rating, it is necessary to apply a safety factor. Sometimes the torque rating from the valve supplier/manufacturer includes a safety factor but this should be clearly stated, not assumed. Selecting an appropriate safety factor depends on the flow media, frequency of operation, and type of operation.

| Application | Safety Factor (%) |

| Type of Operation | |

| ON-OFF | No additional factor |

| Proportional | 20% |

| Frequency of Operation | |

| Daily | No additional factor |

| Weekly | 30% |

| Monthly | 50% |

| Flow Media | |

| Wet or lubricating applications | 20% |

| Dry gas or steam applications | 30% |

| Viscous or abrasive applications | 50% |

Size of Actuator

After determining torque requirements, the selection of an appropriate actuator is the next step. For pneumatic and hydraulic valves, the lower the pilot pressure, the larger the actuator size. Whatever the actuator size is, it must deliver a torque equal or greater than the torque rating of the valve including the safety factor.

For ease in automation, manufacturers make valves with a mounting pad interface in line with ISO 5211. Using this standard ensures that the interface between the valve and actuator are the same for equipment within the same torque range. Also, it helps avoid the use of expensive mounting kits that occupy space and add weight to the assembly. When this standard is followed, it is likely that the valve stem and actuator shaft match perfectly. But in some cases, the actuator shaft is larger, so a simple reducing sleeve properly mates them.

Automated Gate Valves

Automated gate valves are ideal for shutoff applications, where the valve is put in either fully open or fully closed positions. This occurs because the relationship between the vertical motion of the valve and the flow rate is non-linear. When automating a gate valve, the actuator has to turn the stem several times to open or close it. Thus, torque is a key consideration in automating gate valves. Generally, gate valves are automated using pneumatic or electric actuation.

If actuation is pneumatic, it is common to have a diaphragm within a cylinder, which allows air pressure to enter from either or both sides. This cylinder typically seats at the top of the valve. Because it is automated, the control system responds to a measured variable such as flow volume, temperature, pressure, etc.

On reaching the threshold of the measured variable, the control system allows air pressure into the cylinder to move the diaphragm upwards or downwards. As the diaphragm is connected to the valve stem, it moves the valve disc to either close or open the valve. If the valve is to fail-open or fail-close, then actuation needs to be in only one direction, with a spring returning it to its fail-safe position on loss of pressure.

On the other hand, electric actuators utilize a motor to spin the stem to raise or lower the gate. This electric motor connects to the stem using a gear system to increase the torque. Electric actuators are suitable for fail-as-is design, and are faster at operating gate valves.

Automated Globe Valves

The automation of globe valves is similar to that of gate valves as they are both rising stem valves and require linear force to open and close. However, the torque requirement for globe valve actuators is less as the distance traveled by the disc is less. Automated globe valves may utilize pneumatic, hydraulic, and electric actuators.

Automated Butterfly Valves

Of the three valves, butterfly valves offer the easiest route to automation because of their minimal torque requirement. The valve disc pivots at the middle of the pipe with an actuator rotating the disc. A parallel position to the pipe allows flow and perpendicular to the pipe obstructs flow. As a result, butterfly valves bear the classification of “quarter turn” valves. They are ideal for large pipes with minimal debris and are effective in throttling applications.

Recent Comments