The term “Class” seat leakage comes from ANSI/FCI 70-2, a specification that applies exclusively to control valve seat leakage. It does not apply to gate or globe valves, which typically serve in on/off service rather than throttling applications.

Despite this distinction, some end users mistakenly specify FCI 70-2 seat leakage classes for gate and globe valves. Therefore, leading to incorrect testing parameters and potential misinterpretation of valve performance. This article explains why FCI 70-2 is not applicable to on/off valves, highlights the correct standard for gate and globe valves, and also outlines the various valve leakage classifications.

FCI 70-2: Intended for Control Valves Only

The Foreword of FCI 70-2 states that this standard is meant for control valve seat leakage and does not apply to on/off valves. Specifically, the FCI Control Valve and Regulator Section clarified that:

FCI 70-2 is designed for control valve applications where leakage classification is a key performance parameter.

If absolute tight shutoff is required, a different standard should be used.

For on/off valves, the recommended standard is API 598 (Valve Test and Inspection).

Gate and globe valves are not designed as control valves, so, they do not conform to FCI 70-2 classifications.

FCI 70-2 Class V Leakage: Why Gate and Globe Valves Do Not Qualify

According to FCI 70-2, Section 4.2.5, Class V seat leakage applies to:

Critical applications where the valve must remain closed for extended periods under high differential pressure.

Single-seat, unbalanced control valves or balanced single-port designs with high seat tightness.

Valves requiring specialized assembly as well as testing to achieve extremely low leakage rates.

Gate and globe valves do not fit this classification because:

Their design is not based on balanced or unbalanced principles like control valves.

They are serve for isolation rather than precise flow control.

API 598 already defines appropriate seat leakage limits for these valve types.

Therefore, specifying FCI 70-2 Class V leakage for gate or globe valves is incorrect and unnecessary.

API 598: The Correct Testing Standard for Gate and Globe Valves

For gate and globe valves, the correct seat leakage testing standard is API 598. This industry standard defines:

Test procedures for pressure testing industrial valves.

Allowable leakage rates for different valve types and materials.

Requirements for shell, seat, and also closure testing.

Many manufacturers, including Newco and OIC, test their gate and globe valves according to API 598. If an end user requires stricter leakage limits, they must:

Specify API 598 compliance alongside the desired leakage rate limitations.

Request additional testing, which may incur extra costs due to the need for specialized validation processes.

Valve Leakage Classifications Under FCI 70-2

Although FCI 70-2 does not apply to on/off valves, it remains useful for understanding control valve leakage classifications. The six seat leakage classes under FCI 70-2 are:

Class I – No Shop Testing Required

Identical in design to Class II, III, and IV, but no actual test is conducted.

Also called “dust tight”, referring to metal or resilient seated valves.

Class II – Basic Metal-to-Metal Seat Design

Typically for double-port or balanced single-port control valves.

Leakage limit: 0.5% of full open valve capacity.

Test medium: Air at 45 to 60 psig.

Typical construction: Balanced, metal seats with piston rings.

Class III – Improved Tightness Over Class II

Intended for double-port valves with low seat load or single-port valves with lapped metal seats.

Leakage limit: 0.1% of full open valve capacity.

Test medium: Air at 45 to 60 psig.

Class IV – Common for Metal-Seated Control Valves

Used for single-port and balanced single-port valves with Teflon or graphite piston rings.

Leakage limit: 0.01% of full open valve capacity.

Test medium: Air at 45 to 60 psig.

Typical construction: Lapped metal seats with medium seat load.

Class V – For Critical High-Pressure Applications

Used for unbalanced, single-port valves that require exceptional seat tightness.

Leakage limit: 5 x 10⁻⁴ ml per minute per inch of orifice diameter per psi differential.

Test medium: Water at 100 psig or operating pressure.

Class VI – Soft Seat Valves (Tightest Standard)

Used for valves with resilient seating materials like Teflon or elastomers.

Leakage limit: Ranges from 0.15 to 6.75 ml per minute, depending on valve size.

Test medium: Air or nitrogen.

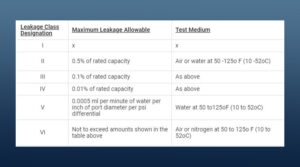

Leakage Class Designation | Maximum Leakage Allowable | Test Medium |

I | x | x |

II | 0.5% of rated capacity | Air or water at 50 -125o F (10 -52oC) |

III | 0.1% of rated capacity | As above |

IV | 0.01% of rated capacity | As above |

V | 0.0005 ml per minute of water per inch of port diameter per psi differential | Water at 50 to125oF (10 to 52oC) |

VI | Not to exceed amounts shown in the table above | Air or nitrogen at 50 to 125o F (10 to 52oC) |

Recent Comments