Plug valves utilize conical and cylindrical plugs to stop or throttle flow in a system. The plug has an opening in the center that allows for flow through the valve in the open position when the cavity is parallel to the flow. When the controlling lever rotates, the plug inside the valve assembly turns and the cavity is perpendicular to the flow which in turn stops the flow.

Plug valve construction allows for quarter turns to completely shut off or open flow. This article covers the different types of plug valves, valve construction and components, typical applications, and maintenance and repair.

Types of Plug Valves

Plug valves can be divided into four major groups, depending on their functionality. These groups are lubricated, non-lubricated, multi-port, and eccentric.

Lubricated Plug Valve

Lubricated plug valves incorporate small channels in the plug construction called radial holes that allow for the flow of a lubricant. The lubricant works along the length of the plug and on its seating surface. Because of the lubricant, the closing, opening, and throttling of a lubricated plug valve is made easier. Similarly, the lubricated plug valve prevents corrosion in the valve and promotes proper seating when closed.

Non-lubricated Plug Valve

Non-lubricated plug valves typically find use in low-pressure systems. Unlike the lubricated plug valve, non-lubricated plug valves have no form of automatic lubrication and are more prone to deterioration and wear. Due to this, non-lubricated valves are cheaper than their lubricated counterparts. This lends non-lubricated valves to best fit applications with small actuator torque requirements.

Multi-Port Plug Valve

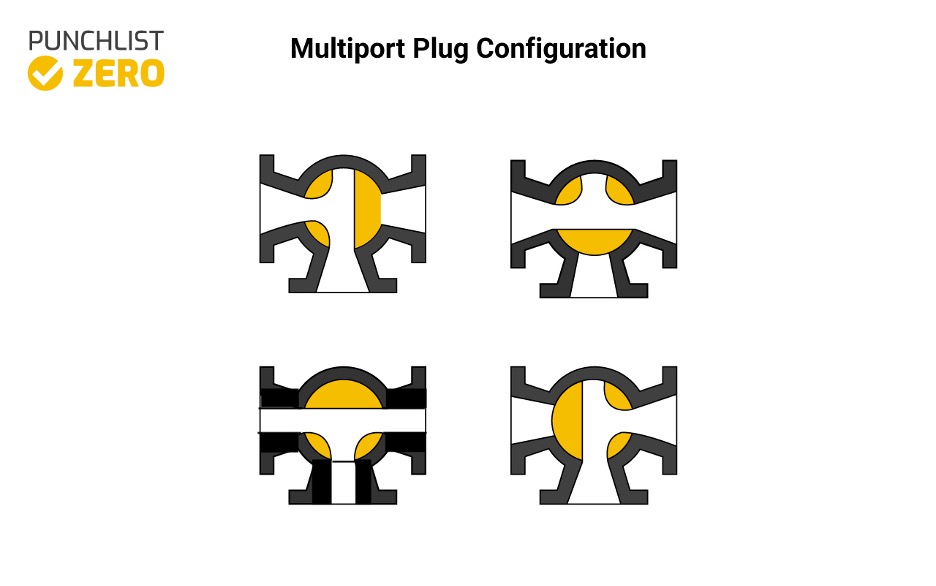

Multiport plug valves control the direction of flow in a system with specified plug cavities. Typically, multiport valves have more than two openings, yet flow is constrained to only two ports. Because of this, the plug design in a multiport plug valve is the biggest design factor to be considered.

Eccentric Plug Valve

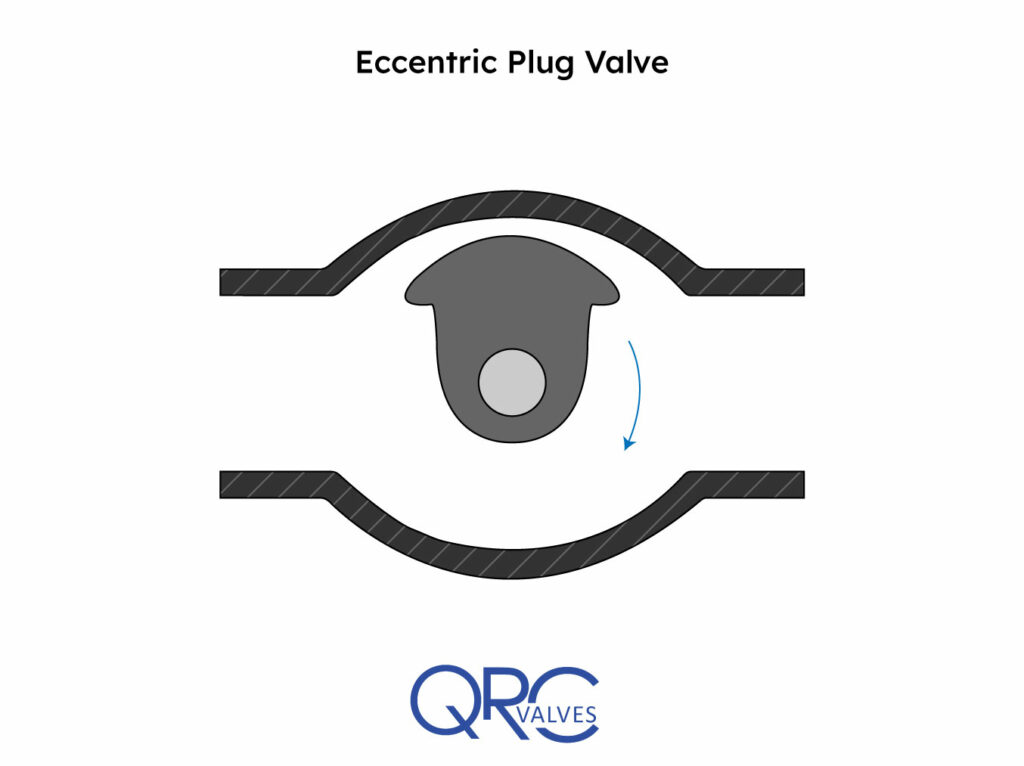

Eccentric plug valves follow an eccentric path when operating the plug, meaning the plug is offset from the centerline of the seating ring. The plug in an eccentric plug valve contacts the seating ring only in the closed position. The open eccentric plug is not in contact with the seating ring when the valve is open.

Valve Construction and Components

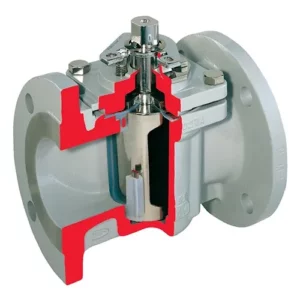

The major components of a plug valve are the plug, stem, handle, and body. The handle of a plug valve attaches to the stem that connects it to the main plug. The plug rotates via the handle torquing on the top part of the valve. Depending on the type of plug valve, the orientation of the stem differs. The main body of a plug valve holds all the major components and keeps the internals of a plug valve safe.

The plug inside a plug valve differs in the shape of its port and overall construction. Depending on the application, the shape of a plug may be rectangular, round, or diamond. Rectangular ports are the most common and allow the most flow through a plug valve. Round ports are also common and apply where the restriction of flow is unimportant. Diamond-shaped ports are best for throttle control in a system.

Applications

Where tight shut-off and flow contamination are important factors in a system, plug valves may be ideal. Typical fluids for plug valve applications include air, slurries, and swage as different types of plug valves offer advantages depending on the type of system.

Plug valves are especially useful in smaller applications as they are simple, quick to use, and relatively easy to maintain. As the design of a plug valve is fairly simple, it allows for minimal flow resistance and leak-tight seals. For higher-pressure systems, manually operated plug valves may pose operating challenges.

The port design configuration is an especially important feature to take into consideration when selecting a plug valve.

Maintenance and Repair

In lubricated plug valves, it is important to ensure proper lubricant dispersal and lubrication. For unlubricated plug valves, proper seating and over tightening are major considerations. Similarly, technicians should ensure proper seating on a routine basis. Checking for leaks in the seating of a plug valve is crucial in ensuring the proper functioning and flow of a system. Depending on the type of flow, the valve should undergo regular inspections for corrosion or any debris that may obstruct any moving components in the valve.

Recent Comments