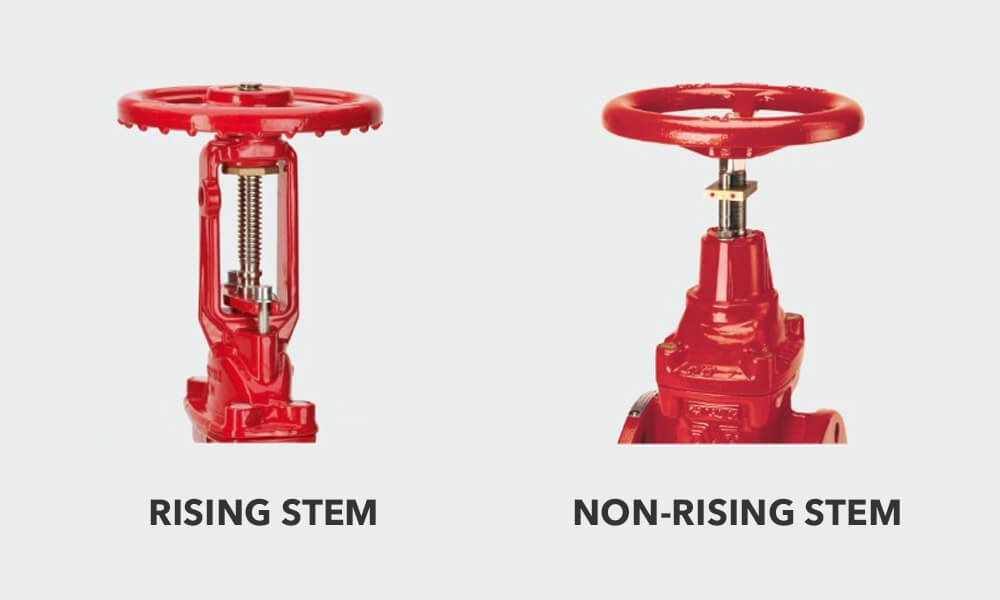

Rising stem valves provide a stem that rises or falls as the valve opens or closes. This means that the actuation system converts rotational motion into linear movement of the valve stem when it is in operation. So, unlike its non-rising counterpart, the valve stem in this design indicates the position of the valve disc. In this article, we will review a rising stem gate valve, a rising stem ball valve, a rising stem globe valve, and compare the rising stem valve vs. its non-rising counterpart.

Rising Stem Gate Valve

Generally, gate valves serve to start or stop flow, rather than regulate it. As a result, the valve disc is completely removed from the flow path when in the open position, which minimizes pressure drop. But when in a completely closed position, there is no flow and no pressure drop.

This feature makes it the go-to option in isolation applications, especially in large-diameter and high-pressure lines. The rising stem gate valve has its thread external to the valve body. So, when the handwheel is rotated, it drives the nut within the bonnet, leading to the raising or lowering of the stem.

Thus, identifying the position of the valve is made easy as the rising stem is always up when open and down when closed. As such, a larger installation height is required for this valve design relative to the non-rising design. Another advantage of this design is the ease of lubrication because the threading is exposed.

Rising Stem Globe Valve

Unlike the gate valve, the rising stem globe valve is suitable for regulating and also isolating flow. However, the pressure drop across this valve is more than in gate valves because of partial obstruction of the flow path when the valve is open. The configuration of globe valves can be for the valve disc to either open or close in the direction of fluid flow. As a result, the kinetic energy of the fluid aids the opening and or closing of the valve depending on the direction of flow.

The normally recommended flow direction is for the flow to enter and go underneath the disc and flow up and around the disc before exiting the valve. Globe valves come with a flow direction arrow on the body. This feature makes globe valves ideal for fail-open or fail-close valve applications. Also, it means that the direction of flow is an important consideration in sizing the actuator. Since globe valves are designed for the disc to push flush up against the seat when closed, there is no “wedging” torque/thrust effect to consider when actuating.

Because the entire pressure exerted on the valve disc is transmitted to the stem, the size of rising stem globe valves is typically limited to NPS 12. From the exterior, the rising stem globe valve looks like its gate valve counterpart but has a shorter stroke. Thus, it enables faster operation and makes it ideal for automation. Another advantage of the globe valve is that it comes in t-shape, y-shape, and angular (90 Degree) patterns, which is helpful when space is limited. The use of rising stem globe valves is common where regulation of flow is desired such as in cooling water systems, fuel oil systems, and turbine drains.

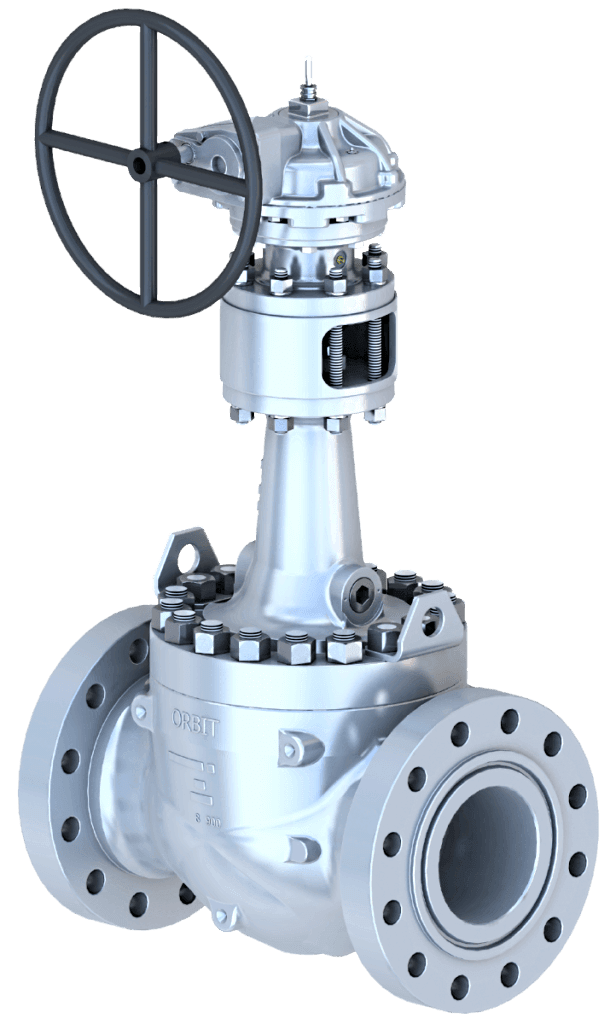

Rising Stem Ball Valve

Similar to the gate valves, rising stem ball valves are used for on and off applications. Because their components are usually all-metal, they operate in a wide range of temperatures between -200℃ and 815℃. Their design is such that there is no abrasion between the ball and seat, nor seal rubbing. Both of these conditions promote the long-term integrity of the valve and minimize the torque requirement for opening and closing the valve.

Another feature that improves the longevity of these valves is that they are self-cleaning. When the valve is closed, the fluid flows along the entire sealing surface, cleaning impurities. And because the ball surface is hardened, it provides great seal performance even when in contact with severe media. Unlike the rising stems of gate and globe valves, ball valve stems rise and fall using stem guide grooves to slide along a rigid guide pin. This ensures proper alignment of the ball. There are two types of rising stem ball valves based on configuration.

Rising Stem vs Non-rising Stem Valve

Both rising and non-rising stem valves enjoy widespread adoption in industry. Choosing between the two requires a careful examination of the benefits of each type.

| Parameter | Rising Stem Valves | Non-rising Stem Valves |

| Appearance | From a distance, it is easy to know if the valve is in the open or closed position. This can be important for operators of complex piping facilities. | Its appearance does not tell if it is in an open or close position. So, an indicator is used to verify this. |

| Position of stem nut and threading | The stem nut, which rotates to achieve lifting or falling of the stem, is located within the bonnet or bracket. Same with the stem threading. Because they are external, it makes it easy for maintenance. | The stem nut here is concealed within the valve body, so it is in contact with the fluid. As a result, it is subject to corrosion, erosion, etc. |

| Mode of transmission | When the handwheel rotates, the stem nut also rotates in place as the stem rises or falls. | The handwheel and the stem are connected so there is no relative motion between them. |

| Installation space | Because of the stem extension, this requires more space for installation. As a result, its application may be limited. | Can easily be installed in tight spaces when there is no room for the extension of the stem. Thus, giving this design a wider range of applications. |

Recent Comments