Valve end connections define how a valve joins to piping systems. This article reviews common end connection types, including Raised Face (RF), Ring Type Joint (RTJ), Butt Weld (BW), Threaded Connection (NPT/BSPT), Socket Weld (SW), and Wafer Connection types. It explains how each connection works, when to use it, and how pressure class, process medium, sealing, and installation influence selection.

Engineering Parameters Governing Selection of Valve End Connections

The selection of valve end connections should never be in isolation. They must align with piping design codes, process conditions, and the overall maintenance philosophy of the facility. Key engineering parameters include internal pressure, operating temperature, allowable leakage rate, mechanical loads, and inspection accessibility.

Pressure and Temperature Ratings

End connections must comply with the pressure and temperature limits defined by applicable standards such as ASME B16.5, the ASME B31 series, or EN 1092. At elevated pressures and temperatures, gasketed joints may experience relaxation, creep, or extrusion, while welded joints generally provide higher structural integrity.

Process Medium and Leakage Risk

The nature of the process fluid strongly affects connection selection. Hazardous, flammable, or toxic media typically require connections with minimal leak paths. In such cases, welded or metal-to-metal sealing connections are often preferred over threaded or gasket-dependent joints.

Mechanical Loads and System Stress Impact on Valve End Connections

Piping systems impose axial, bending, and torsional loads on valve connections due to thermal expansion, vibration, and weight. Welded connections distribute stresses more uniformly, while flanged and wafer connections require careful bolt load management and pipe support to avoid misalignment.

Installation, Inspection, and Maintenance Strategy

Connections that allow easy disassembly are advantageous in systems requiring frequent inspection or valve replacement. Conversely, permanently welded connections are better for long-term installations with minimal intervention.

Types of Valve End Connections

In industrial piping systems, the selection of valve end connections is a critical design consideration. The end connection not only determines how the valve integrates with the pipeline but also influences factors such as sealing integrity, ease of installation, maintenance requirements, and overall system reliability.

The most widely used valve end connections include:

Raised Face (RF) Flanged Connections

Raised Face flanged connections rely on a gasket compressed between two raised sealing surfaces. The raised face concentrates bolt load onto a smaller gasket area, improving sealing efficiency compared to flat face designs.

Typical Applications

RF flanges are a mainstay in oil and gas, chemical processing, power generation, and general industrial piping. They are suitable for a broad range of pressure classes and temperatures when paired with the correct gasket material.

Engineering Considerations

Factors such as bolt preload, surface finish, and operating conditions impact gasket performance. Improper bolt tightening can result in uneven gasket compression, leading to leakage. RF flanges are also sensitive to flange rotation under bending loads, particularly in large-diameter piping.

Ring Type Joint (RTJ) Flanged Connections

RTJ connections achieve sealing through a precision-machined metallic ring gasket seated in a groove between mating flanges. When bolted, the ring undergoes controlled plastic deformation, forming a tight metal-to-metal seal.

Typical Applications

RTJ flanges are commonly specified for high-pressure and high-temperature services, particularly in upstream oil and gas, refining, and petrochemical facilities where sealing reliability is critical.

Engineering Considerations

RTJ connections require precise machining tolerances and controlled bolting procedures. Ring gaskets are generally not reusable, and surface damage to the groove can compromise sealing performance. Despite a higher initial cost, RTJ connections offer superior long-term reliability under severe service conditions.

Butt Weld (BW) Connections

Butt weld connections involve welding the valve directly to the pipe using a full penetration weld. The resulting joint becomes an integral part of the piping system, eliminating gasketed interfaces and mechanical fasteners.

Typical Applications

BW connections are ideal for high-pressure, high-temperature, and critical process services. They are particularly suitable for hazardous fluids and systems designed for continuous operation.

Engineering Considerations

Welding procedures must comply with applicable codes, and having qualified welders is necessary. Welds are often subject to radiographic or ultrasonic inspection. While BW connections provide excellent integrity, valve removal requires cutting the pipe, increasing the outage duration during maintenance.

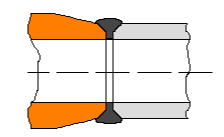

Socket Weld (SW) Connections

Socket weld connections consist of inserting the pipe into a recessed socket and applying a fillet weld around the joint. The socket provides alignment while the weld supplies mechanical strength. In the sample image below, ‘D’ represents nominal diameter, ‘B’ is the socket bore diameter, while ‘J’ is the minimum depth of the socket.

Typical Applications

SW connections are commonly used for small-diameter, high-pressure piping where threaded connections are unsuitable.

Engineering Considerations

Having a small expansion gap between the pipe end and the socket bottom is necessary to accommodate thermal expansion. Crevice corrosion can occur in the socket area, making SW connections less desirable for corrosive services or where cleanliness is critical.

Threaded Valve End Connections (NPT and BSPT)

Threaded connections seal through tapered threads that create interference between mating components. Sealants, such as PTFE tape or anaerobic compounds, are used to fill thread clearances and enhance sealing.

Typical Applications

Threaded ends are generally limited to small-bore piping and low-pressure services, including utilities, instrument air, and auxiliary process lines.

Engineering Considerations

Threaded joints are susceptible to leakage under vibration and thermal cycling. Care must be taken to avoid over-tightening, which can cause thread damage or cracking. Compatibility between NPT and BSPT standards must also be verified during the design process.

Wafer Connections

Wafer-style valves are clamped between two pipe flanges using through-bolts. The valve body itself does not carry flange faces, relying on the piping flanges for alignment and sealing.

Typical Applications

Wafer connections are commonly used for butterfly and check valves in low to medium-pressure systems where compactness and reduced weight are beneficial.

Engineering Considerations

Accurate flange alignment is critical to prevent valve distortion and leakage. Wafer valves may not provide full isolation in dead-end service unless specifically designed and supported.

Comparative Evaluation of Valve End Connections

The table below provides a high-level engineering comparison of common valve end connection types.

| Connection Type | Pressure Capability | Sealing Reliability | Ease of Maintenance | Installation Complexity | Typical Use Cases |

| Raised Face | Medium to High | Moderate to High | High | Moderate | General process piping |

| Ring Type Joint | Very High | Very High | Moderate | High | Severe pressure and temperature |

| Butt Weld | Very High | Very High | Low | High | Critical and hazardous services |

| Threaded | Low | Low to Moderate | High | Low | Utilities and small bore lines |

| Socket Weld | Medium to High | High | Low to Moderate | Moderate | High-pressure small-bore piping |

| Wafer | Low to Medium | Moderate | Moderate | Moderate | Space-constrained installations |

Design Integration and Lifecycle Considerations for Valve End Connections

From a system design perspective, valve end connections should be evaluated over the full lifecycle of the piping system rather than based solely on initial installation cost. Early-stage decisions on connection type directly influence constructability, inspection scope, maintenance intervals, and the risk profile of the operating plant.

Design Considerations

During the design phase, engineers must consider how each connection behaves under long-term operating conditions, including thermal cycling, pressure fluctuations, vibration, and external loading from piping supports. Gasketed connections may require periodic bolt retightening or gasket replacement, while welded connections generally reduce ongoing intervention but increase the consequence and complexity of future modifications.

Regulatory Requirements

Inspection and regulatory requirements also play a significant role in lifecycle evaluation. Welded joints may require non-destructive examination at installation and during service, whereas flanged joints allow visual inspection and easier leak detection but introduce additional potential leak paths. In regulated industries, inspection accessibility can significantly influence outage planning and compliance costs.

Maintenance and Installation Effort

Maintenance strategy is another critical consideration. Systems designed for frequent valve replacement or process reconfiguration often favor flanged or mechanical connections, while long-life, steady-state systems benefit from welded or metal-to-metal sealing connections. Although higher-integrity connections may increase upfront fabrication and installation effort, they often reduce unplanned downtime, environmental exposure, and safety risk over the operating life of the system.

How QRC Valves Supports Proper End Connection Selection

Selecting the appropriate valve end connection is a critical engineering decision that impacts system performance, safety, and long term reliability. QRC Valves supports customers by helping identify valve end connection options that align with service conditions, operating requirements, and applicable industry standards.

Through technical product expertise, documentation support, and manufacturer backed certifications, QRC Valves assists in evaluating valve end connections based on factors such as pressure class, temperature range, inspection considerations, and maintenance requirements. This helps ensure the selected valve configuration supports reliable operation over the life of the equipment.

For additional technical guidance on valve end connection options, contact us to discuss your application requirements.

Recent Comments