Ball Check Valves – Operation, Diagram vs. Swing Valves

The purpose of using a ball check valve is to prevent reverse flow in a pipe. Ball check valves achieve this by using a spherical ball inside the flow path that permits flow in only one direction. In this article, you will learn how ball check valves operate, review a diagram, and compare it vs a swing check valve, and vs a regular ball valve.

How Ball Check Valves Operate

A typical ball check valve consists of a spring-loaded ball that pushes up against a seat inside the valve body. When pressurized fluid flows in one direction, it pushes the ball against the spring, causing it to rise and fluid to pass through. But if non-pressurized fluid flows in the opposite direction, the ball lowers down or against the seat due to the restoring spring force and closes the flow path.

In addition to the spring action, the ball has a slightly larger diameter than that of the seat/through-hole. Also, the valve seat conically tapers to properly guide the ball, providing a positive seal. These features enable the valve to function efficiently while maintaining a simple design. Due to how the valve operates, the pump’s capacity must always be sufficient to overcome spring stiffness. If there is a drop in pump capacity, then a smaller ball or spring with less stiffness should be used.

Application of Ball Check Valves

The simplicity and effectiveness of the ball check valve design make it popular in a variety of applications. One common industry that uses these types of valves is the plumbing industry. A host of water supply systems, including sprinklers, sump pumps, and water heaters, deploy them to ensure unidirectional flow. Because they prevent backflow, potentially contaminated water downstream of the valve cannot reenter the supply line. This is a key feature in water supply systems.

Ball check valves fashioned from PVC, brass, or stainless steel are used in potable water applications. Most applications require metallic valves to deliver increased durability. Another common use of ball check valves is in pumping stations. The presence of solid contaminants in such systems can increase the pumping requirement. So, the self-cleaning action of the ball during operation helps in maintaining valve performance. Also, it minimizes the need for intervention making it low maintenance.

In factories that use injection molding processes to push plastic forward without any backward slip, ball check valves are popular. In these applications where the production fluid is not water, compatibility could become an issue, so the selection of the right valve material is essential.

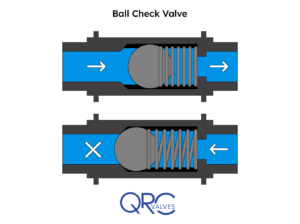

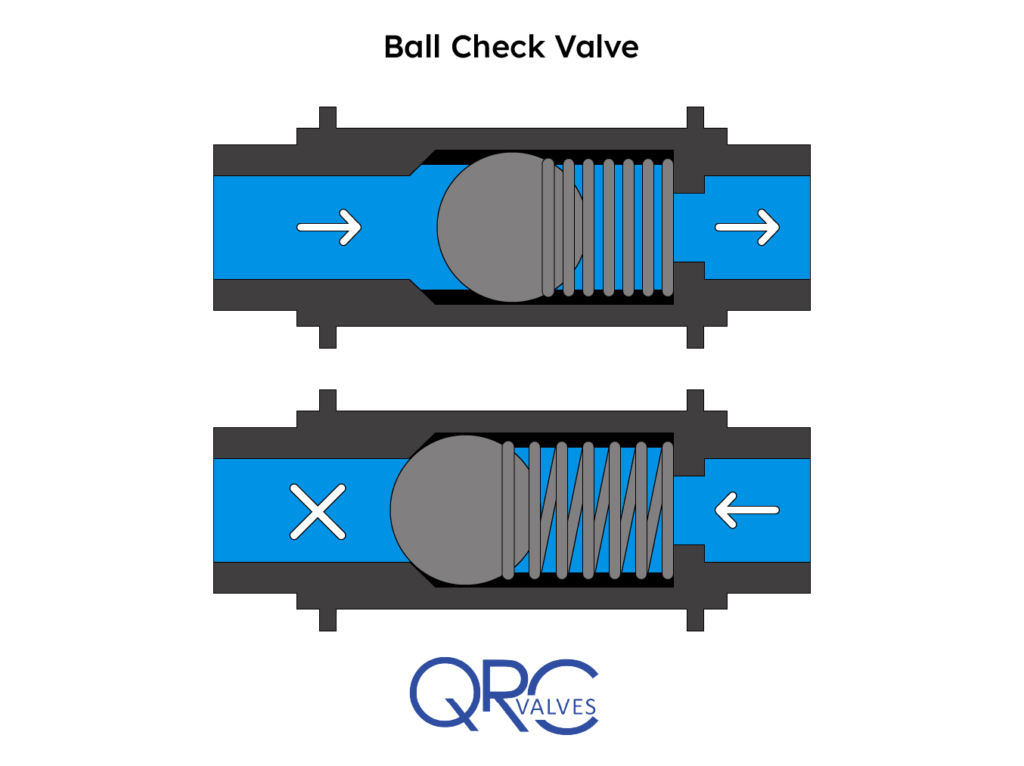

Ball Check Valve Diagram

Like other valves, a ball check valve has a body, seat, and an obturator. But its key feature is its mechanism to prevent backflow via a ball and spring system.

When the pressure upstream increases to a certain point, the valve opens and allows flow in the desired direction. In practice, this pressure is referred to as cracking pressure and must be attained at the inlet side to open the valve and allow flow to progress downstream.

Also, the cracking pressure should exceed the back pressure in the system. If this pressure is not attained, probably due to the pump switch off or poor performance, the spring force closes the valve, as in the ‘B’ part of the diagram. Alternatively, some valve designs use a free-floating ball with no spring. To achieve the same function, there is a need for an inverse flow, or the configuration should be such that gravity can restore the ball to the seat when the inlet is below cracking pressure.

Ball Check Valve vs Swing Check Valve

Swing check valves perform the same function as ball check valves in ensuring unidirectional flow in pipes. However, there are a few differences as the table below highlights.

| Ball Check Valve | Swing Check Valve |

| The obturator is a ball that lifts at cracking pressure and returns by either spring action or gravity. | For a swing check valve, the obturator is a disc that swings on a shaft or hinge to restrict or permit flow. |

| It is versatile in applications as it is suitable for either horizontal or vertical flow. | Although it is used in both horizontal and vertical flow, it does not support downward vertical flow. |

| The operation mechanism is simple, but the ball design makes it more expensive than the swing check valve. | Because it uses a flapper in place of a ball, it is cheaper. The cost difference could be significant when working on large projects with several valves. |

| The water hammer is easily minimized by increasing the ball size. | Its swinging action exacerbates any water hammer issues. |

| Flow capacity is hindered by the presence of the ball along the flow path. However, this makes it more compact and able to fit tight areas. | Delivers larger flow capacity, especially when using the top hinge configuration. But requires more space for the obturator to flap open and close. |

Ball Check Valve vs Regular Ball Valve

Even though a ball check valve and the regular ball valve have the same type of obturator, there are several differences between them as the table below highlights.

Note: A Regular Ball Valve is not self-operating and will not stop flow in either direction unless it is closed using the available actuation method.

| Ball Check Valve | Regular Ball Valve |

| Flow is unidirectional. | Flow can occur in either direction as long as the valve is in the open position. |

| The ball is solid, so it rises from the seat to allow flow and returns to the seat to obstruct flow. | Because the ball has a hollow section, rotation of the ball on the seat allows or hinders flow. Full flow is achieved by aligning the ball’s hole so that it is parallel to the pipe/flow. |

| The manner of operation makes it self-cleaning, so it is ideal for sterile applications such as pharmaceuticals, beverages, and bioprocessing. | It is difficult to clean so not advisable to use it in sterile applications. |

| It does not require external intervention to operate. Flow pressure operates the valve. | The valve requires an actuator to operate. |